Testing (Hydrotest)

Hydrostatic testing is an integral part of quality control. Hydrostatic tests are performed to determine the structural integrity

and fitness for use of a variety of objects including gas cylinders, storage tanks, and chemical pipelines. The test works

by filling the object with water until it's completely full and then pressurized-ensuring that it can hold up under

pressure without bursting open at any seams nor allowing leaks from within its structure. Hydrostatic testing also provides

a level of confidence that the object will hold up under pressure and withstand exposure to corrosive environments

without bursting open at any seams nor allowing leaks from within its structure.

How Can We Help?

HYDROLINE conducts valve testing in accordance with API standards and the best available techniques

to ensure the optimal results. Apart from testing of safety and relief valves, we also carry out

testing of isolation valves. Our team has the expertise in hydrostatic testing which is critical

to maintain the safety standards and prolonged vessel.

Hydroline provides Hydrostatic & Pneumatic Testing for pressure ranges up to 30,000 psi

Our Testing Service

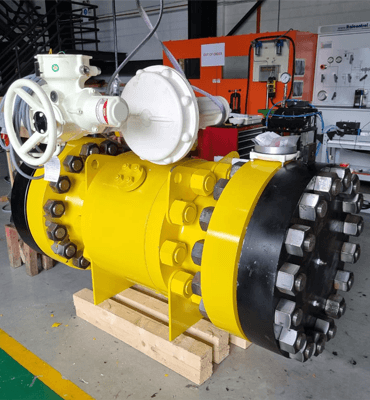

Valve Testing

- DBB Valves

- DIB Valves

- Gate Valves

- Globe Valves

- Ball Valves

- Butterfly Valves

- Needle Valves

- Check Valves and etc

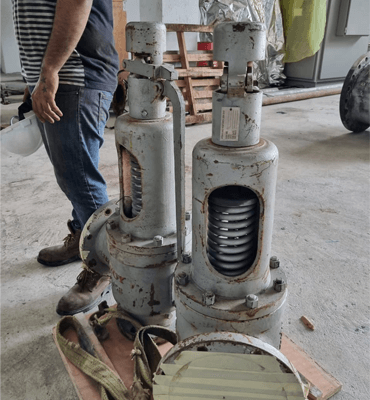

Relief Valves

- Pressure Relief Valves (PRV)

- Pressure Safety Valves (PSV)

- Pilot-Operated PRV

- Temperature Actuated PRV

- Vacuum Relief Valves

Pressure Vessels

- Fabricated Test Units

- Pipelines

- Boilers

- Spools

- Hoses

- Manifolds and etc

All our testing procedures, specifications and requirements are based on American Petroleum Institute (API) standard.

How It Work?

1

Consult

We receive your inquiries,

get to know your needs and requirements.

2

Plan

We will start planning and drafting

the proper equipments and procedures

for the project.

3

Execute

The project will be executed on your

request until job completion.